Individual schools or multi-academy trusts are acting to make their operations more sustainable. How suppliers are working towards greater sustainability is a growing factor in procurement decisions. RM’s efforts thus far to operate more sustainably have already been recognised. However, achieving truly sustainable operations involves extensive planning, strategy and execution. Read on to learn more about our sustainability commitments and our work to deliver them.

Climate Change

The single biggest challenge we face is climate change, and if we do not reduce greenhouse gas emissions, we will experience temperatures not seen for around 150 million years.

Today, the carbon dioxide level in the atmosphere is 414 parts per million, a 48% increase from levels pre-industrialisation. The impact on our climate is already apparent. At RM, we are reviewing the scenarios for different temperatures to better understand how climate change may affect our business. We will publish our initial findings in our next Annual Report. However, many of our strategies and plans already offer resilience to extreme weather for us, our supply chain and our customers. For example:

-

Digitisation - increasing digital services such as online data storage or exam marking improves security, reduces travel and paper and printing transactions and costs, enables secure remote access to learning and data, and reduces energy consumption by up to 93%2

-

Recycled materials - working with our supply chain to obtain products that contain recycled materials means that we not only support the growth of recycling activities but in the future, this should mean that material costs are more easily controlled as recycling is less carbon and water intensive than mining, chemical processing and material manufacture which should keep prices lower

Reducing carbon emissions

So that RM contributes to containing climate change in line with the Paris Agreement3, in 2021, we committed to achieving the UK Government target of 78% carbon reduction by 2035. We also set our net zero target for our direct fuel and electricity use (scope 1 and 2 emissions) by 2035. To measure our progress, we set our baseline for carbon emissions as 2015, the year we stopped manufacturing IT equipment and became the company we are today. Between 2015 and 2021, our carbon impact has reduced by some 67%. Some of that reduction was a result of the pandemic. However, by introducing hybrid working, we hope to maintain much of this saving in 2022.

Then, using a strategic facility planning approach, which aligns facility needs to our strategic business plan, we can better adjust facility size to occupation levels and location, enabling further reductions in energy demand. In addition, using a tool to help us select the most energy efficient appliances and IT, lighting, heating and cooling equipment will deliver further energy efficiency savings.

To be transparent, we have published our group Carbon Reduction Plan. It meets the UK Government Procurement Policy Note 06/21, is published by the Cabinet Office, and will be updated annually. We will also build a plan for each of our divisions to give their respective directors flexibility about how they too can reduce their carbon impacts.

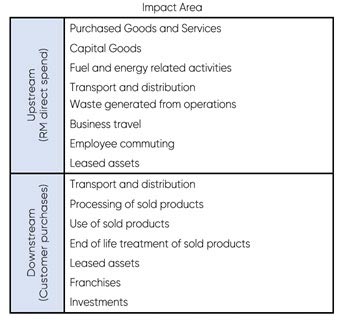

Scope 3 emissions, as shown in Table 1, are trickier to measure, yet we did not want to estimate them as we are planning to develop Net Zero targets for scope 3 emissions too. We committed to collecting and reporting some scope 3 data in our next annual report, which will include:

- staff commuting

- business travel (air travel is already reported)

- RM operational wastes arising from our facilities

- product packaging wastes

- waste electronic and electrical equipment

- battery wastes

In addition, we are investigating ways to collect data directly from our supply chain so we can capture the remaining aspects of scope 3 emissions. This will allow us to set carbon reduction and net zero targets for scope 3 emissions with our supply chain.

Table 1 - Impact Areas that make up Scope 3 Emissions

Ending waste to landfill

We know that to achieve net zero in an economical way, we also need to be zero waste and operate a circular economy. Therefore, RM has multiple workstreams supporting its target to be zero waste to landfill by 2030. These include a packaging waste project that aims to:

- unpackage every item we sell from our warehouses, around 36,000 different products

- measure, weigh and record each packaging material by product

- test the need for each packaging type

As the project progresses and we start to draw conclusions about changes that may be possible, we will work with our supply chain to:

- eradicate excess packaging

- remove unnecessary single-use plastics

- replace necessary single-use oil-based plastics with recycled content plastics

- replace hard to recycle materials with easy to recycle materials

In addition, we have started to design our new products so that the packaging is part of the product itself. We have already mandated that the manufacturers of our new products replace virgin oil plastics with recycled content plastics which contain waste originating from crops – mainly wheat and sugar cane. These are more tactile materials for children and have a lower carbon impact while meeting all the necessary safety standards.

Working with customers and suppliers

Later this year, we will also start work with our customers, identifying what is top of their environmental agenda so we can develop joint plans to reduce these impacts.

We are also planning to work with our supply chain to develop joint plans to address major impacts and risks. We will also discuss our new supply chain charter, which sets out our minimum sustainability requirements.

Together we can fix this.